Renewable Energy

Qualitätsystem

-

ISO 9001:2015 / JISQ9001:2015

Qualitätssicherung und Qualitätsmanagement

-

ISO 14001:2015

Umweltmanagement Standard

-

ISO 45001:2018

Arbeitsschutzmanagement

-

ISO/IEC 17025:2017 (LAB TAF)

Beurkundetes Umweltsmanagementsystem anerkanntes betriebsinternes Labor mit integrierter Ausrüstung.

-

RoHS Compliant

We do not intentionally use any hazardous material required by “RoHS2 EU Directive 2011/65/EU and RoHS3 EU Directive EU/ 2015/863” within compounding process and any others processes.

-

REACH Compliant

We hereby declare that all products(articles) have been designed and manufactured do not contain SVHC above the threshold value.

Kataloge Herunterladen

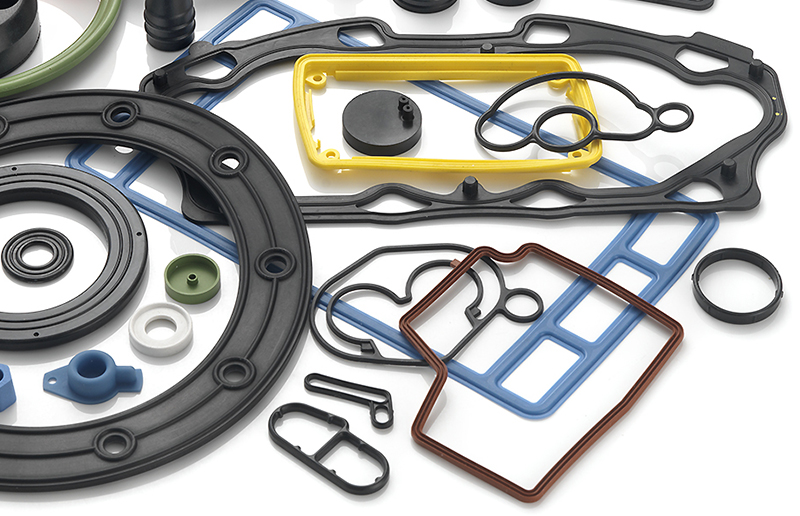

Today, environmental protection issues and the frequent occurrence of extreme climates have prompted countries to consider long-term plans for energy transition in order to reduce energy pollution and improve safety (such as nuclear energy). The coming of the era of renewable energy is a trend which is as unstoppable as the emergence of electric vehicles.

Over time, technology breakthroughs and cost reductions spur the growth of the renewable energy market. Energy transformation towards renewable energy such as wind, hydropower, solar, biomass and geothermal energy is the prevailing trend.

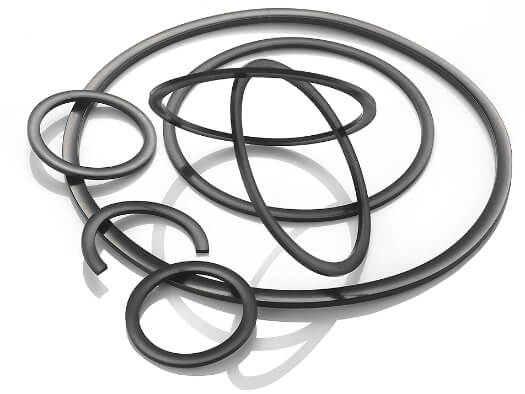

GMORS has developed suitable rubber seal compound design according to different renewable energy application requirements, providing protection against prolonged exposure to the ultraviolet degradation effects of sunlight, with resistance to ozone, salt spray and other extreme environments. GMORS application team uses finite element analysis (FEA) to simulate sealing applications, optimize seal design and engineering performance along with customer verification, developing seals that can achieve low friction, zero leakage and ease of installation with extended service life.